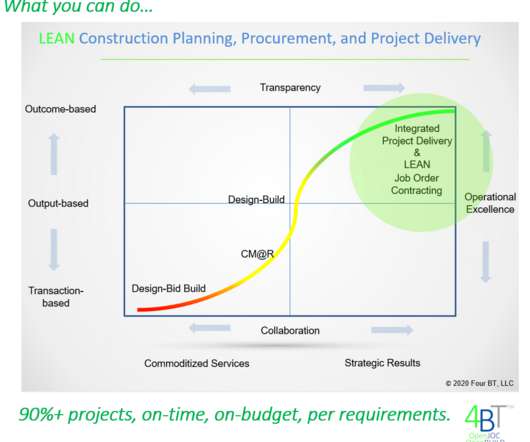

LEAN Construction Project Delivery and Facilities Operations, Maintenance, and Life-cycle Management

Job Order Contracting

AUGUST 30, 2018

LEAN METHODOLOGY. LEAN methodology was first introduced by Henry Ford, later expanded by Toyota, and subsequently adopted by numerous manufacturing and service sectors. An understanding of LEAN fundamentals and their application to O&M and overall Facilities Management is of great benefit to all participants and stakeholders.

Let's personalize your content