DfMA Approach to Mass Timber Design: Engineering a Greener Future

Civil + Structural Engineer

DECEMBER 18, 2024

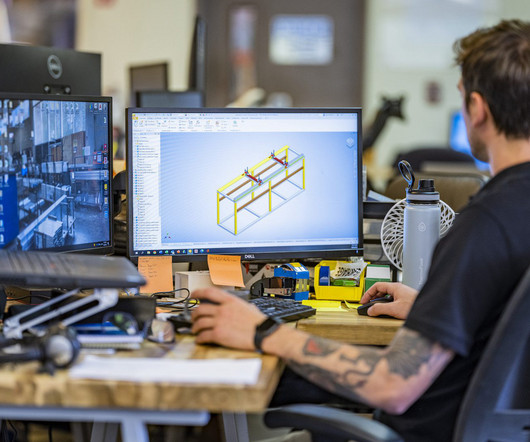

By focusing on standardization, modularization, and prefabrication, DfMA allows engineers to design components that are easier to manufacture and simpler to assemble onsite. Compared to concrete prefab elements, mass timber can be up to 5 times lighter per unit of volume, making it a force to be reckoned with in the prefabrication market.

Let's personalize your content