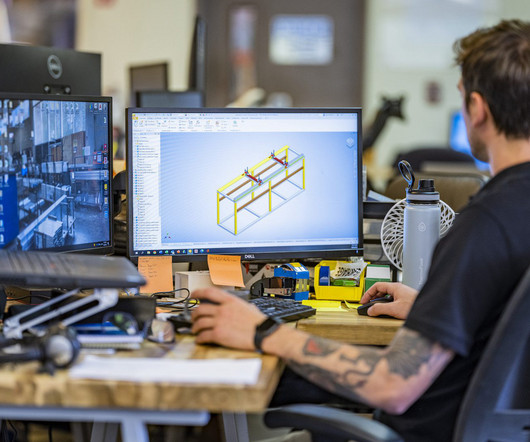

Streamlining Construction with Prefabricated Utility Room Solutions

UK Construction Blog

FEBRUARY 26, 2025

The post Streamlining Construction with Prefabricated Utility Room Solutions appeared first on UK Construction Blog. As the demand for streamlined building processes grows, prefabricated utility rooms have become a key solution, helping construction companies reduce installation time, cut costs, and improve overall project efficiency.

Let's personalize your content