The three Ps of prefabricated EIFS: Preparation, production, placement

Construction Specifier

DECEMBER 23, 2024

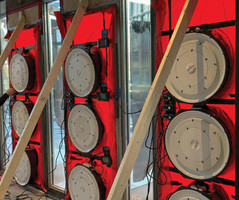

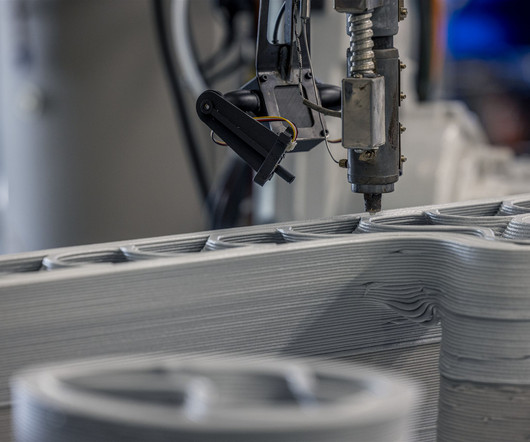

EIFS-clad wall panels can be fully prefabricated, from the structural backup to the finish coat. EIFS is also a cost-competitive cladding in many markets. Prefabricated panels may also include fenestration and other elements of the exterior wall. EIFS is lightweight and uses relatively few materials.

Let's personalize your content